In the maritime industry, the spotlight has fallen on the critical rocking test of ship deck cranes, including the Flow Boom Crane, which is of great significance for maintaining the safety and performance of these essential maritime lifting equipment.

In the ever - evolving maritime industry, MAXTECH continues to lead the way with its innovative products. The company is proud to announce the launch of its latest offering, the 2T25m Hydraulic Oil Pipeline Slewing Crane. This cutting - edge crane has been specifically designed to meet the diverse needs of modern ship operations, combining high - end technology with robust construction for optimal performance. MAXTECH is advancing the on - site installation work in an orderly and systematic manner.

What is Rocking test of Ship Deck Crane?

– Rocking test of ship deck crane is carried out to ascertain the wear down of the sleeve bearing of the deck cranes by measuring the play (relative movement) between the inner and outer bearing race. This measurement indicates the rate of wear.

– Usually the wear down is also identified by analyzing the grease sample taken from the bearing housing.

– The Rocking Test needs to be carried out according to manufacturer recommendation.

– No loads shall be to the crane hook, positions below are usually marked and used always as a datum reference.

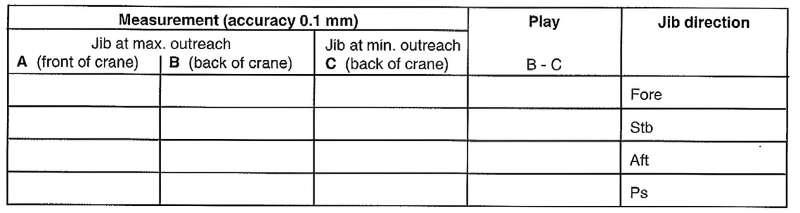

– Measurements are typically taken in four positions on the slew bearing, with the jib pointing:

1. Extended towards forward

2. Extended Towards aft

3. Hard to port side

4.Hard to starboard

-‘Rocking tests’ are carried out every six months and that the results are recorded and monitored in order to ensure the wear tolerances remain within the limits.

Procedure of rocking test of Ship deck crane

Preparation

1. The ship should be adjusted to have the least possible trim, preferably on an even keel.

2. Bad weather or windy conditions should be avoided.

3. No cargo or bunkering operations are allowed.

4. The crane hook should be free of any load.

5. A properly working and calibrated dial gauge, not a Vernier caliper, is used.

Rocking test of deck crane

Procedure

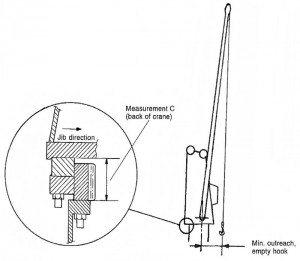

1. The usual rocking test reference points, usually two on the front and rear bottom plate of the crane, are always used for these tests.

Rocking test of deck crane

Tabulation and fault finding procedure

rocking test measurement logging table

2. Measurements are recorded with an accuracy of 0.1mm.

3. If measurement B – measurement C = 0 or is negative, the measurement is incorrect and should be re - checked.

4. If measurement B – measurement A = 7 or more, the crane must be stopped and not used until the bearing is replaced, tested, and surveyed again.

5. The maximum allowed play:Cranes with single ball race slew bearings are at particular risk. These cranes must have rocking tests carried out according to the manufacturer’s instructions to ensure the bearing race wear is within permitted limits.

+For roller bearings = 1.5 mm

+For ball bearings = 3.0 mm.

What is the action taken if deviation is out of limit?

1. Measurements are recorded every 6 months. If the wear rate increases, the greasing should be increased. When adding grease, the bearings should be rotated to spread it evenly. Pump in grease until old grease squeezes past the seal (Purging).

2. Purged grease removes contaminants from the bearing. If you feel grit or metal chips when rubbing your finger, it indicates bearing wear.

3. Grease can dry out over time, causing condensation in the bearing. To avoid this, grease should be added at least every six months, even when the crane is idle.

4. If the wear is out of limit, the bearing must be replaced. If the wear occurs prematurely, the reason needs to be investigated.

5. If the wear is close to or at the limits, operating the cranes below the max SWL and hoisting with the extended jib should be restricted. The jib should be operated within a shorter outreach.

This comprehensive and regular testing procedure is essential for ensuring the smooth operation and safety of ship deck cranes, such as the Flow Boom Crane, in the challenging maritime environment.

At present, the crane is in the rigorous process of on - site installation and comprehensive testing. MAXTECH's professional and experienced team ensures precise installation in strict accordance with standard procedures and comprehensively evaluates its performance through a series of stringent tests, especially the rocking test that simulates the dynamics at sea.

With its unwavering commitment to quality, MAXTECH is dedicated to presenting excellent products to customers, facilitating safe and efficient maritime operations. We firmly believe that the 2T25m Hydraulic Oil Pipeline Slewing Crane will surely set a new benchmark in the maritime industry with its outstanding performance.

Post time: Dec-27-2024