Dust Control ECO Port Hoppers 99% Dust Catching Perfect for Cement Powder

Maxtech have accumulated lots of experience in handling with cement powder.

The dust absorbing performence can reach 99% ;

Maxtech ECO hopper for cemment powder help to make your port PERFECT clean.

General introduction

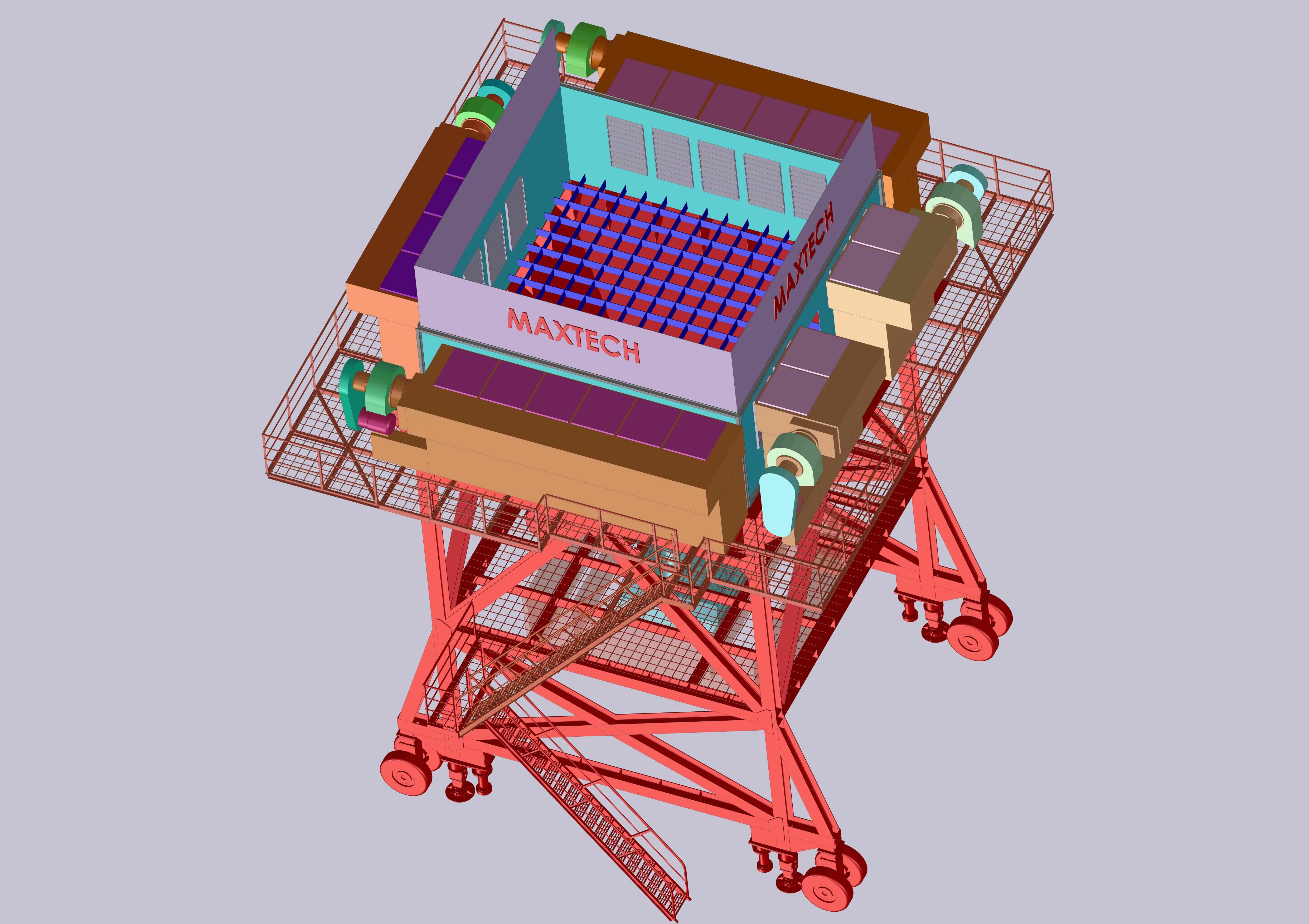

This equipment is mainly for cement unloading and loading, the dust removal system is arranged on the hopper to control the dust generated during the unloading process, and the weighing system controls the load weight to each vehicle, and through the Intelligent Identification System (IIS) to ensure the feeding spouts with the truck receiving spouts accurately docking;

Main structures of the equipment: steel structure frame, hopper body (storage hopper and weighing hopper), electric intelligent identification discharge gate, electric winding and expansion silo, dust removal device, weighing device, compressed air system,

mobile mechanism, electronic control system, operation room, diesel generator power system , etc.

The electricity type is 380V AC (± 10%), 50 Hz, three-phase four-wire.

Send us the enquiry with your working requirements, we gonna offer you a free crane quotation .

MAXTECH Customized Hopper for a various range material with the below options:

1, Weighing System ;

2,Dust Control System;

4,Intelligent Identity System(IIS);

5,Diesel Generator Power Station;

6,Self-driving Moving System;

Paramenters of 80m3 ECO hopper for cemment powder for your reference:

| Unloading efficiency |

Unloading efficiency is 300~600 t / h / unit

|

|||

| Applicable materials |

Cement POWDER

|

|||

| Hopper Cone volume and material |

80 cubic meters and above The upper bucket is 7.3 * 7.0m2 and the material is T8mm * Q345B

|

|||

| Hopper inclination |

~ |

|||

| Maximum load |

200t

|

|||

| Process |

Ship→ Crane→ Dust removal hopper→ Truck

|

|||

| Operation control mode |

Operation control mode :100m;

|

|||

| Important parameters of equipment | Overall height :18900 | Upper opening size:7300×7000 |

Upper wind protection baffle height:2000

|

|

| Lower spouts number :2 | Lower spouts size:Φ580 | Spouts height from the ground:4650mm

|

||

|

Control mode of feeding port opening and closing valve: gate valve

|

||||

| Dust removal parameters |

Dust removal method and dust removal principle: negative pressure dry filter bag &filter collector

|

|||

|

Filter wind speed 1-1.5m/min |

Total filtration area ≥890m2

|

Dust removal rate ≥98%

|

||

|

Negative pressure ≥5000Pa

|

Blow pressure 0.5-0.7MPa

|

※Dust concentration of the exhaust port ≤30mg/m3 |

||

|

Important parameters of the generator set |

Total power rate:132KW |

Brand: Cummins Silent mute type

|

||

|

Electric type :380V 50Hz 3P |

Diesel fuel tank volume: 1500L Per hour oil consumption :25L

|

|||

|

Important parameters of the weighing system |

Number of weighing sensor:4 |

Weighing precision :±1%

|

||

|

weighing hopper design

|

Weighing control mode: resistance and strain type

|

|||

| Intelligent identification system (IIS system) |

Grab open identification control: distance sensor, displacement sensor

|

Induction control of dust removal system: laser to radiation sensor |

||

|

Lower feeding port identification control: mercury sensor, image information processing |

Data processing: PCL programming and intelligent module |

|||

International leading acceptance standard – high standard&full covarage

1,Our acceptance criteria: dust concentration is less than 30mg/m3 at 5m distance from the top of the hopper;

2,Bottom loading: at the 2m of the truck, dust concentration is less than 30mg/m3;

The dust concentration is lower than 20mg/m3 at the outlet of the fan at 2m distance.

3,Our above testing criteria is leading advanced comparing with both domestic and foreign industry.