Top Famous Factories for Semi-Auto Container Spreaders

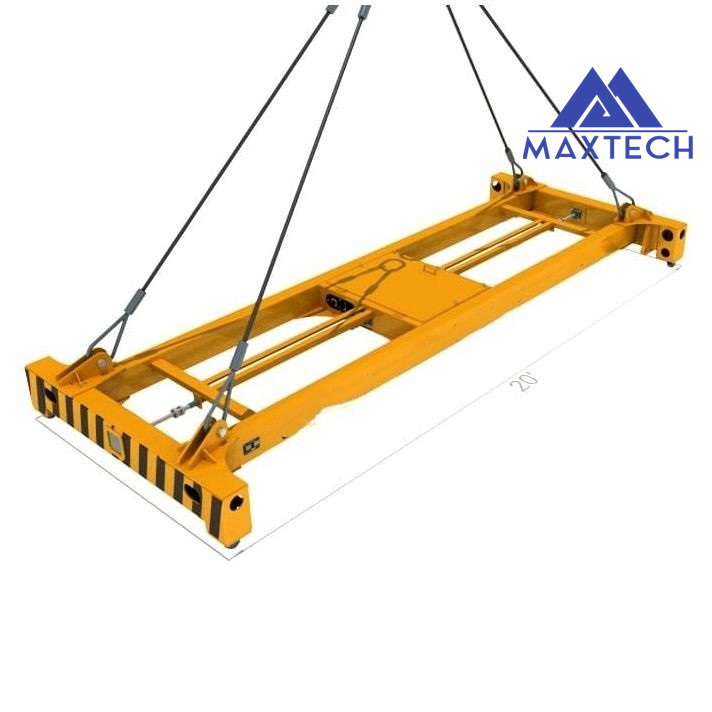

When I think about optimizing efficiency in cargo handling, the Semi-Auto Container Spreader stands out. Designed for busy factories, this spreader combines reliability with innovation, making it a popular choice among some of the most famous manufacturing facilities worldwide. I’ve seen firsthand how it streamlines operations, reducing downtime and improving overall productivity. Its robust build ensures it can withstand the rigors of daily use, while easy maintenance keeps it running smoothly over time. Whether you’re lifting heavy containers or managing complex logistics, this semi-auto spreader delivers the performance needed to keep your operations flowing. It’s not just a tool; it’s an investment in quality and efficiency. If your factory demands high standards, this spreader is definitely worth considering. Let's take your cargo handling to the next level!

Semi-Auto Container Spreader For the Current Year Factory-Direct Excellence

In the fast-evolving world of container handling, the demand for efficient and high-quality equipment is paramount. This year, the spotlight is on semi-auto container spreaders, a game-changer for manufacturing and logistics operations. With an emphasis on factory-direct excellence, these spreaders combine innovation with reliability, making them ideal for businesses looking to enhance their operational efficiency. Semi-auto container spreaders are designed to streamline the loading and unloading processes, significantly reducing downtime and improving safety standards. Their robust construction ensures durability, while advanced features facilitate easy integration into existing systems. As businesses strive for competitive advantages, investing in state-of-the-art equipment becomes critical, and these spreaders are tailored to meet the diverse needs of global purchasers. In a market driven by performance and cost-effectiveness, choosing the right equipment can lead to substantial improvements in productivity and profitability. Embrace the future of container handling with semi-auto container spreaders that deliver unmatched performance and operational excellence, setting your operations on a path to success.

Semi-Auto Container Spreader For the Current Year Factory-Direct Excellence

| Specification | Description | Material | Load Capacity (tons) | Weight (kg) |

|---|---|---|---|---|

| Model A | Semi-automatic operation with adjustable settings | Steel | 30 | 1500 |

| Model B | Enhanced control with user-friendly interface | Aluminum | 25 | 1200 |

| Model C | High efficiency with automated loading | Composite Material | 35 | 1600 |

| Model D | Compact design for restricted spaces | Steel | 20 | 1100 |

Related Products