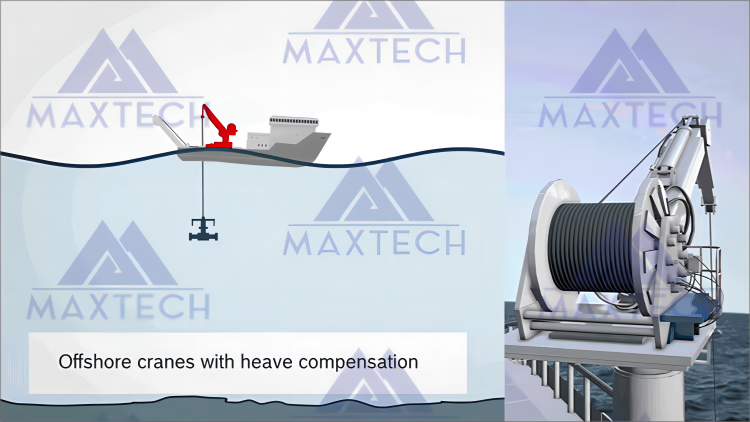

Offshore cranes play a crucial role in the oil and gas industry, as well as in various maritime and offshore construction activities. These heavy-duty machines are designed to handle the lifting and positioning of heavy loads in challenging offshore environments. In recent years, technological advancements have led to the development of offshore cranes with Active Heave Compensation (AHC), which have significantly improved the efficiency and safety of offshore lifting operations.

What is an offshore crane with AHC?

An offshore crane with AHC is a specialized lifting equipment designed to compensate for the vertical movement of the vessel or platform on which it is installed. This technology allows the crane to maintain a constant hook position relative to the seabed, even in rough sea conditions. AHC systems utilize advanced sensors and control algorithms to actively adjust the hoisting motion, ensuring that the load remains stable and secure throughout the lifting operation.

The key advantage of AHC-equipped offshore cranes is their ability to mitigate the effects of vessel motion, such as heave, pitch, and roll, which can significantly impact the safety and efficiency of lifting operations in offshore environments. By actively compensating for these dynamic forces, AHC cranes enable precise and controlled load handling, reducing the risk of accidents and improving overall operational productivity.

Difference between a marine crane and an offshore crane

While both marine cranes and offshore cranes are used for lifting and handling operations at sea, there are distinct differences between the two types of equipment. Marine cranes are typically installed on various types of vessels, such as cargo ships, container ships, and bulk carriers, to facilitate cargo handling and general lifting tasks during maritime transportation. These cranes are designed to operate in relatively stable sea conditions and are not equipped with specialized features to compensate for vessel motion.

On the other hand, offshore cranes are specifically designed for use in offshore oil and gas platforms, drilling rigs, and construction vessels, where they are subjected to more challenging environmental conditions, including rough seas, high winds, and dynamic vessel motions. Offshore cranes are engineered to meet stringent safety and performance standards, with features such as AHC systems, heavy-duty construction, and enhanced corrosion protection to withstand the harsh offshore environment.

The incorporation of AHC technology sets offshore cranes apart from marine cranes, as it enables them to maintain precise load control and stability, even in adverse sea states. This capability is essential for lifting operations in offshore industries, where safety, efficiency, and precision are paramount.

Advantages of offshore cranes with AHC

The integration of AHC technology in offshore cranes offers several significant advantages that contribute to the overall safety and efficiency of offshore lifting operations:

1. Enhanced load stability: AHC systems actively compensate for vessel motion, ensuring that the load remains stable and secure throughout the lifting process. This minimizes the risk of load swing, collisions, and potential damage to the cargo or equipment being lifted.

2. Improved operational efficiency: By maintaining a constant hook position relative to the seabed, AHC cranes enable smoother and more controlled lifting operations, reducing downtime and increasing productivity in offshore activities.

3. Safety and risk mitigation: The precise control and stability provided by AHC technology contribute to a safer working environment for personnel involved in lifting operations, as well as for the assets and infrastructure on the offshore platform or vessel.

4. Extended operational capabilities: AHC-equipped offshore cranes are capable of performing lifting tasks in a wider range of sea conditions, including rough seas and challenging weather, expanding the operational window for offshore activities.

5. Reduced wear and tear: The active compensation provided by AHC systems helps to minimize the dynamic loads and stresses on the crane structure and components, leading to reduced maintenance requirements and extended equipment lifespan.

Overall, offshore cranes with AHC technology represent a significant advancement in the field of offshore lifting and handling equipment, offering improved safety, operational efficiency, and performance in demanding offshore environments.

Applications of offshore cranes with AHC

Offshore cranes with AHC find diverse applications across various sectors of the offshore industry, including:

1. Offshore oil and gas exploration and production: AHC-equipped cranes are used for lifting and handling heavy equipment, supplies, and personnel transfer operations on offshore drilling rigs, production platforms, and support vessels.

2. Offshore construction and installation: These cranes play a critical role in the installation of subsea infrastructure, such as pipelines, subsea modules, and offshore wind turbine components, where precise and controlled lifting is essential.

3. Offshore maintenance and repair: AHC cranes are utilized for maintenance and repair activities on offshore installations, including the replacement of equipment, components, and structural elements in challenging sea conditions.

4. Offshore decommissioning: During the decommissioning of offshore platforms and structures, AHC cranes are employed for the safe and efficient removal of heavy topside modules and subsea infrastructure.

The versatility and advanced capabilities of offshore cranes with AHC make them indispensable assets for a wide range of offshore operations, contributing to the overall success and safety of offshore projects.

Future developments and trends

As the offshore industry continues to evolve, there is a growing focus on the development of advanced technologies and innovations to further enhance the capabilities of offshore cranes with AHC. Some of the key future developments and trends in this field include:

1. Integration of digitalization and automation: The incorporation of digitalization and automation technologies into AHC systems will enable real-time monitoring, data analysis, and predictive maintenance, optimizing the performance and reliability of offshore cranes.

2. Enhanced load handling capacities: Ongoing research and development efforts are aimed at increasing the lifting capacities and operational capabilities of AHC-equipped offshore cranes to meet the growing demands of offshore projects.

3. Environmental sustainability: There is a rising emphasis on the integration of eco-friendly features and energy-efficient solutions in offshore crane designs, aligning with the industry's commitment to sustainable and responsible operations.

4. Adaptation to new offshore challenges: With the expansion of offshore activities into deeper waters and more remote locations, offshore cranes with AHC will need to adapt to new challenges, such as extreme weather conditions and complex lifting scenarios.

In conclusion, offshore cranes with Active Heave Compensation (AHC) represent a significant technological advancement in the field of offshore lifting equipment, offering enhanced safety, efficiency, and performance in challenging offshore environments. The integration of AHC technology enables these cranes to mitigate the effects of vessel motion, maintain precise load control, and expand their operational capabilities, making them indispensable assets for a wide range of offshore applications. As the offshore industry continues to evolve, ongoing developments and innovations in AHC-equipped offshore cranes will further contribute to the advancement of offshore operations and the overall safety and sustainability of the industry.

Post time: Mar-25-2024