In the current booming development of the global port logistics industry, efficient and intelligent loading and unloading equipment has become a key factor in enhancing port competitiveness. Recently, the highly anticipated MAXTECH 45T fully automatic telescopic spreaders have reached a crucial assembly and testing stage.

This 45T fully automatic telescopic spreader, specifically designed for port operations. Its rated lifting capacity (for a single container) reaches 45T, and the load on the four - corner lifting lugs is 42T. This strong load - bearing capacity enables it to easily handle the lifting of various large - scale goods. Whether it is a fully - loaded container or large - sized bulk goods, it can carry out lifting operations safely and stably.

The "fully automatic telescopic" function is a major highlight of this spreader. It only takes 35S to expand and contract, driven by a hydraulic motor through a sprocket/roller chain drive. It can quickly and accurately adjust the spreader's shape according to the size specifications of different goods, greatly shortening the loading and unloading time and significantly improving operational efficiency. The rotation time of the spreader's twist lock is approximately 1S. It adopts an ISO floating twist lock, driven by a hydraulic motor. The flipping time of the guide plateis between 5 - 7S, driven by 6 hydraulic devices. These flexible component operations further enhance the spreader's adaptability to different goods.

The center - adjustment mechanism can achieve an adjustment of ±800mm, driven by 4 cylinders. It can ensure precise centering during the lifting process, improving the stability and safety of operations. The spreader has a control voltage of DC 24V, a total power of 11 KW, a power supply voltage/frequency of 380V/3P/50HZ, and an ingress protection rating of IP55. This can effectively resist the intrusion of dust and water, making it suitable for relatively harsh port operating environments. Its self - weight is approximately 11.5T. It is suitable for handling ISO standard 20’, 40’, and 45’ containers, and can operate stably in a working temperature range of - 45 ° to +50 °, whether in severe cold or high - temperature environments.

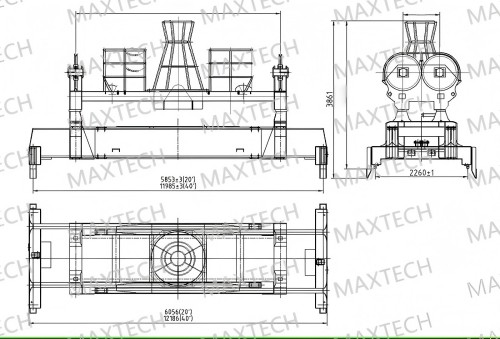

The follow below is technical drawing of container spreader:

Complementary to the MAXTECH 45T fully automatic telescopic spreader is the 45t40m rail - mounted mobile port crane. This crane has an arm length of 40 meters and a lifting capacity of 45 tons, with strong operating capabilities. Its operating speed ranges from 0 - 25m/min, and it can achieve a 360° free rotation (wheel), enabling it to move flexibly along the track and effectively expand the operating coverage.

This assembly and testing process covers several crucial aspects. The mechanical structure stability test is a strict inspection of the overall structural strength and reliability of the spreader and the crane, ensuring that the equipment can still operate safely and stably under long - term high - load operations. The precision adjustment of the automatic telescopic function focuses on optimizing the spreader's adaptability to different goods' sizes, striving for millimeter - level precision. The collaborative operation simulation with the crane simulates real - world operation scenarios to test the coordination between the two, ensuring efficient and smooth cargo handling during actual port operations.

Only after the MAXTECH 45T fully automatic telescopic spreader passes these strict tests and all performance indicators meet industry standards will it be officially put into port operations. The successful application of this spreader is expected not only to greatly improve the port's cargo handling capacity and operational efficiency but also to effectively reduce manual intervention, minimize safety risks caused by human errors, and provide a safer working environment for port operators.

Post time: Mar-31-2025